| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : LCD

Model Number : MZ2017111706

Certification : ISO SGS CE

Place of Origin : Jiangsu, China

MOQ : 1 set

Price : negotiable

Payment Terms : T/T, Western Union, MoneyGram, D/P, D/A, L/C

Supply Ability : 10 Sets per Month

Delivery Time : 55 Working days after receiving 30% deposit

Packaging Details : Nude package in 40' container

Material of the blade : Cr12

Type : Pipe Mill

Pipe Material : Steel

Roller material : 45# steel

Application : Drain pipe

Voltage : 360V 50Hz 3Phase/Customized

Cutting system : flying saw cutting

Weight : 12 Ton

Pipe shape : Round or square or customized

Computer : PLC Panansonicc

Discription of the machine

Welded tube mill is complete equipment for welding steel pipes. It rolls the strip or plate then welds the tube to steel pipes by BH welding or submerged arc welding. Welded pipe making machine is composed of uncoiler, leveling machine, butt welder, loop, straightening machine and high frequency equipment.

Main Technical parameters

Roll former

1). Production site requirements for producing high-frequency welded pipes:

2). Power supply: 380V/22V; 50HZ three-phase four wire

3). the power of the main forming machine: 400KW high-frequency welding

4). the power of the main motor:440 kw

5). The power of the auxiliary motor: 200kW.

6). the total capacity of the production lion: 1040KW

7). Site:80mx5m

8). The room to place the high frequency equipment:5mX5mX2.8m.

9). The valume of the water tank:30m m3/h

10). One set of High pressure pump

11). One set of Air Compressor

12). Three-five-ton lifting equipment, 2 sets

13). material : high frequency cable, wiring device, magnet and saw blade

14). Warranty: one year

15). production time: 50 days

Flying Saw

| Name | Discription |

| Forming Pipe OD | Φ15mm~φ63mm |

| WT of pipe | 0.7-3.2m |

| Fixed Cutting length | 4~12m |

| Cutting Accuracy | ±5mm |

| Saw blade cutting motor | AC15kW |

| Carriage driving motor | DC 15kW |

| Cutting Speed | Max. 90m/min |

| max cutting | 13times/min |

Working procedure

Coil Loading → Uncoiling→ Accumulator → Forming, HF welding, Debarring, Cooling, Sizing, Straightening →cutting saw →Transmitting → Packing → Storage

Machine discription

This type of High frequency welding pipe roll forming machine is includes all the parts to assemble a complete production line, and with diffents shapes and sizes of welding pipe, we have professional technician team to design the machine according to your requirements.

Standard shapes and sizes of welded pipes

| Profile | Thickness | Material |

| Square 25×25 | 0.8-2mm | Cr12 |

| Square 30×30 | 0.8-2mm | |

| Rectangular 30×40 | 0.8-2mm | |

| Round ¢22 | 0.8-1.5mm | |

| Round¢25 | 0.8-1.5mm | |

| Round ¢32 | 0.8-2.5mm | |

| Round ¢40 | 1-3mm | |

| Round ¢42 | 1-3mm | |

| Round ¢49 | 1-3mm | |

| Round ¢50 | 1-3mm | |

| Round ¢60 | 1-3mm |

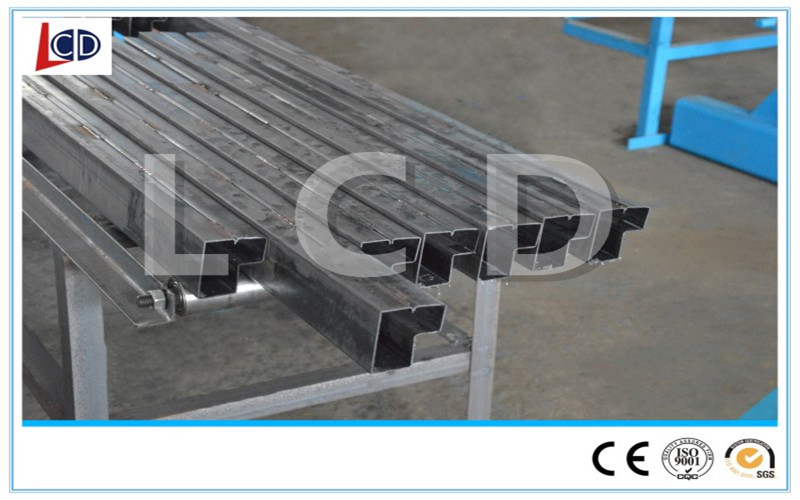

Machine pictures

|

|

PLC Control Steel Pipe Roll Forming Machine , Square Tube Making Machine 50Hz Images |